measuring zince thickness|galvanizing thickness standards : convenience store With this Coating Thickness Measuring Device, layer thicknesses on metallic surfaces can be reliably determined. The Coating Thickness Measuring Device has a measuring range of 1500 µm. This means that the Coating Thickness Measuring Device is used, for example, in a paint shop, for incoming goods inspection or for an expert. Resultado da 26 de out. de 2022 · 2. MeSeems. Esta opção em sites para ganhar gift card também possui uma versão em aplicativo disponível na Play Store e nele você também acumula .

{plog:ftitle_list}

22 de fev. de 2024 · A série Quilos Mortais está de volta à programação da RECORD com episódios inéditos nas noites de sexta-feira , a partir das 22h45. Nesta semana, o .

There are two methods for measuring the zinc coating thickness of hot-dip galvanized steel; a magnetic thickness gauge and optical microscopy. The simplest and non-destructive way is to utilize a magnetic thickness gauge, .

AND METHODS OF MEASURING SURFACE HARDNESS AND THICKNESS OF COATINGS Technical Report TR-#105(Rev.Ø) 19650 Pauling Foothill Ranch, CA 92610-2610 Tel (949) 460-2100 Fax (949) 460-2300 . Zinc Excellent corrosion protection for steel; economic & safe Connecting elements, auto and construction industry, plant

The thickness of zinc plating that you should use depends on the environment that the component is in. We have produced some recommendations based on what we find is suitable for most of our customers. The corrosion resistance of the zinc depends on two things:The Elcometer range of mechanical coating thickness gauges provides cost-effective dry film thickness measurement. Mechanical Coating Thickness Gauges are suitable for working in high risk areas such as high temperature or flammable atmospheres, underwater or where the risk of explosion is high and could be triggered by the use of an electronic .With this Coating Thickness Measuring Device, layer thicknesses on metallic surfaces can be reliably determined. The Coating Thickness Measuring Device has a measuring range of 1500 µm. This means that the Coating Thickness Measuring Device is used, for example, in a paint shop, for incoming goods inspection or for an expert.Coating Thickness Measurement Solutions Option #1. The PosiTector 6000 F Microprobe series consists of 3 gages which measure coatings up to 45 mils (1150 microns) thick, making them ideal for non-destructive measurement of most coatings on as low as 80 mil diameter (14 gauge) ferrous wires. For best results on small diameters, a quick release .

zinc coating thickness standard

Coating thickness measurement/Dry film thickness measurement is used to determine the thickness of coatings on components and to monitor the coating process. Our measuring instruments solve a wide range of applications in coating thickness measurement. . Zinc or nickel on steel or iron; copper on brass or stainless steel; copper on epoxy .

Contact the GalvInfo Center The usual criterion for determining the expected service life of zinc coatings is thickness: the thicker the coating, the longer the service life. Hot-dip galvanizing (batch or continuous), electrogalvanizing, zinc plating 1.7 mils (43µm) Zinc Spraying (metallizing) 1.9.Coating Thickness vs. Coating Weight. The service life of zinc coatings is a linear function of the zinc coating thickness. However, zinc coating thickness alone can be deceiving when evaluating zinc applied by different processes. In addition to thickness, the amount of available zinc per unit volume, or density, is also important.

Similarly to Average thicknesses, it is at the plater’s discretion where to measure the product unless the measuring location is indicated on the print. If the range is ≤ 0.00015” (150uin) it is treated as a single average with the mid point of the range being the target average and the definition of average thickness above applies.Ultrasonic coating thickness gages (e.g. PosiTector 200) emit a high frequency sound pulse that travels into the coating via a coupling gel and reflects from ANY surface that is different in density.Paint thickness readings are obtained by measuring the time taken for the ultrasonic signal to propagate from the probe to the coating/substrate interface and back.

micron to gm m2

The zinc thickness is calculated by subtracting the paint thickness from the combined paint/zinc thickness measurement. When disabled, the gage will operate like a conventional combination ferrous/non-ferrous instrument (similar to PosiTector 6000 FNS probe).

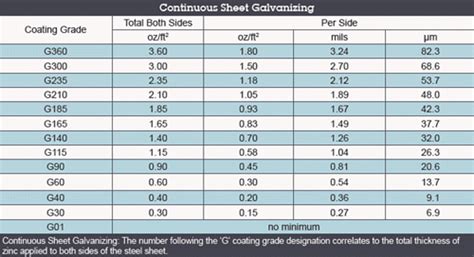

Accurate thickness measurement for both alloy deposits can be obtained using proper thickness standards. . The exact thickness of the zinc standards is not as critical. Use valid zinc calibration standards that are currently in use. For customers testing low alloy, 6-12 percent nickel specifications, parts typically 5-10 μm, see Table 1.AN034 Measuring the copper thickness in plated through-holes on PCBs 0.57 MB AN044 Determining the thickness of thermally sprayed aluminium (TSA) coatings on stainless steel 1.66 MB AN047 Measuring the zinc plating on nails with PHASCOPE® PMP10 0.52 MB AN091 Different ways to achieve valid measurement values and optimize measurement .that it is difficult to directly technique for measuring coating measure the thickness accurately and repeatedly. For example, a G90 coating contributes about 1.6 mils (0.0016 inches, or about 42 microns) to the total thickness of the . sheet, zinc-5% aluminum alloy-coated sheet, and zinc-aluminum-magnesium alloy-coated sheet. There are Maintaining plating thickness as specified by a buyer and applicable standards is critical for the quality and longevity of the end product. In order to be sure that a component’s thickness is correct and consistent, tight .

how much zinc per ton

A reversible anvil lets you adapt the gauge to the shape of the object you are measuring. Use the round face on the anvil to measure the wall thickness of pipe, tubing, and other curved surfaces. Use the flat face to measure sheet metal, paper, and other flat stock.AND METHODS OF MEASURING SURFACE HARDNESS AND THICKNESS OF COATINGS Technical Report TR-#105(Rev.Ø) 19650 Pauling Foothill Ranch, CA 92610-2610 Tel (949) 460-2100 Fax (949) 460-2300 . Zinc Excellent corrosion protection for steel; economic & safe Connecting elements, auto and construction industry, plant

Measure the thickness of zinc coatings ; Analyze the microstructure of the coating and the base material ; Check adhesion; Fig. 1: Galvalume, etched with 1 % Nital, 500x. . As zinc coatings vary in hardness and thickness, they behave differently during metallographic preparation. In addition, some zinc coatings react with water, which makes . The authoritative public forum for Metal Finishing since 1989 -----Thickness of phosphate coatings and thickness measurement . Q. Dear all, We are facing the problem of bore diameter oversize (Plug gauge going loose in transmission gear inner dia.) after Phosphating process, and phosphating layer observed 6-7 micron after 6 min timing.

Use a magnetic gauge such as the PosiTector 6000 F1 or PosiTest FM to measure the thickness of both the zinc and paint layers together. Subtract the zinc layer thickness to provide the paint thickness value. PLUS: Fast and simple for any magnetic gauge. MINUS: Gauge doesn’t know which layer is responsible for changes in thickness. .

The coating thickness is chosen on the basis of the type of coating system and the required protection. The ISO 10683 standard "Fasteners — Non-electrolytically applied zinc flake coating systems" includes a table which indicates the extent to which the level of corrosion protection depends on the thickness of the coating (by means of the duration of the salt spray .Lastly, a standard exists for Zinc in which a higher gauge number indicates a thicker sheet. The chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from the selected gauge size standard. Eddy current techniques are used to nondestructively measure the thickness of nonconductive coatings on nonferrous metal substrates. A coil of fine wire conducting a high-frequency alternating current (above 1 MHz) is used to set up an alternating magnetic field at the surface of the instrument's probe. When the coating thickness probe is .To determine the number of atoms thick: To determine how many atoms span the thickness on one side, we first convert the thickness into picometers: 0.0025 cm x (1 x 1010 pm / 1 cm) = 2.5 x 107 pm Using the fact that one atom of zinc has a radius of about 133 pm, and therefore a diameter of about 266 pm, we can divide the total distance by the .

The answer is simply that it is difficult todirectly measure the thickness accurately. For example, a G90 coating contributes about 1.6 mils (0.0016 inches) of thickness to the final coated sheet. For a . zinc and the coating thickness is not quite the same as for a G40 galvanized coating, although the difference is The reason for this is that measuring thickness correctly and precisely is challenging. A G90 coating, for example, adds around 1.6 mils (0.0016 inches, or 42 microns) to the total thickness of the coated sheet. . While the coating includes around 8% to 10% iron, the density is somewhat greater than zinc and the coating thickness is slightly .Practical Measuring method of Thickness for Zinc-Coating in Steel Transmission Towers Shi-jun Huang 1, a, Hai-feng Zhu 1,b , Tian-wen Wang 2,c and Hao Chen 2,d 1 State Grid Jiangsu Econgomic Research Institute, Nanjing Jiangsu 210008,China 2 School of civil engineering, wuhan university, Hubei Wuhan 430072, China [email protected], .

hot dip galvanizing thickness

galvanizing thickness standards

galvanizing thickness

WEBFree Chips. Exclusive game offers. Exclusive welcome bonuses. Discover the power of .

measuring zince thickness|galvanizing thickness standards